When a Nottinghamshire-based fencing contractor approached Corden Group for a stainless steel and glass balustrading kit, it was immediately clear the project would require a tailored solution. The contractor, who typically specialises in industrial fencing installations for businesses and schools, faced two main challenges: the bespoke sizing of the decking and unfamiliarity with stainless steel and glass balustrade installation.

The Challenge

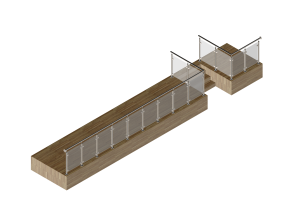

The project called for two L-shaped runs of balustrading, each requiring precision fabrication to fit the custom-length decking. Complicating matters, the contractor had never installed this type of balustrade before, and the deadline was tight – just two weeks to deliver a complete solution.

Additionally, the decking’s proportions created an aesthetic issue. The shorter end required a central post due to spacing rules (no more than 1200mm between posts). Using standard spacing along the longer run would have resulted in glass panels that appeared disproportionately wide.

The Solution

Corden Group engaged it’s sister company, DG Scott Engineering to deliver a fully fabricated, ready-to-install kit. The approach combined technical precision with clear, user-friendly guidance:

- 3D Design Visualisation – A full 3D mock-up was created during the quoting stage, allowing the client to see exactly how the balustrade would look before committing to the order.

- Optimised Post Layout – The number of posts on the longer run was increased to match the aesthetic balance of the shorter side.

- Custom Instruction Booklet – DG Scott produced a bespoke installation guide, tailored to the client’s decking measurements. It detailed all components, included accurate post positioning, and provided clear step-by-step instructions for assembly.

- Fabrication & Sourcing – Posts and handrails were fabricated to specification, with posts drilled and tapped for easy glass clamp installation. Custom-sized glass panels—three different sizes in total—were sourced to fit perfectly between posts.

- Efficient Delivery – The complete kit was packaged across two pallets, ready for the client to collect in one trip from DG Scott’s Blidworth facility.

The Outcome

The contractor praised both the quality of the fabrication and the clarity of the custom instruction booklet, which made the unfamiliar installation process straightforward. The packaged kit arrived complete, well-organised, and ready for immediate use.

Installed on the decking, the stainless steel and glass balustrading achieved a sleek, professional finish that complemented the setting. The balance of spacing and the precise fit of each component delivered both structural integrity and visual appeal.

Key Achievements

- Delivered a bespoke balustrading solution within a tight two-week timeframe.

- Provided a complete, ready-to-install kit with tailored guidance for a first-time installer.

- Ensured a balanced and aesthetically consistent design through custom post spacing and glass sizing.

Find out more about our balustrades and handrails or contact a member of our team to discuss your project.